| 晶界扩散Dy-Al-Ga对钕铁硼磁体的磁性能和微观组织的影响 |

b. 江西理工大学,江西省稀土磁性材料及器件重点实验室,江西 赣州 341000

b. Jiangxi Key Laboratory for Rare Earth Magnetic Materials and Devices, Jiangxi University of Science and Technology, Ganzhou 341000, China

Nd-Fe-B系烧结磁体具有高饱和磁通密度、高矫顽力、高磁能积等优异的磁特性,因此被广泛用于磁性器件的关键部位,如风力涡轮机和电动车牵引电动机[1-5]. Nd-Fe-B磁体在这些领域中的使用越来越多,但是却因为相对较差的高温性能使其发展受到阻碍.比如在汽车的应用中,磁体需要在高达150 ℃的温度下进行长时间的工作[6-8].对于任何稀土过渡金属磁体来说,在高温下发展的矫顽力基本上有2种可能性,要么改善固有温度依赖性或者开发足够的矫顽力抵抗温度,以便当磁体暴露于高温时能够保持足够的矫顽力.虽然,钕铁硼的固有性质很难改变,但是重稀土金属元素Dy、Tb等由于磁晶各向异性场(HA)的增加,Nd的位置可以相对容易的对矫顽力作出实质性的改善.当然,添加重稀土元素的缺点是它们与RE2Fe14B晶格中的Fe形成反铁磁耦合,导致饱和磁化强度大大降低[9].为了尽量少地牺牲饱和磁化强度,一种新的提高矫顽力的方法在2000年由Park等[10]提出.后来陆续有研究人员使用Tb或Dy等高HA的重稀土元素Dy、氧化物(如DyO)、氟化物(如DyF3)沿着晶界处,然后进入RE2Fe14B晶粒的外壳,形成核壳型结构.由于Nd-Fe-B磁体在成核型矫顽力机制的基础上产生矫顽力,只需要在晶粒的外壳上向内增加HA的深度至少1 μm,这是因为在RE2Fe14B晶粒中的任何额外的重稀土元素仅仅对磁化的较低值有贡献.该核壳结构是通过将重稀土以某种形式(通常为氟化物)置于烧结磁体的表面上,然后在一定温度下进行扩散热处理,随后进行低温二级时效来完成.重稀土元素沿着晶粒,然后在RE2Fe14B晶粒中形成核壳结构.到目前为止,已经有含镝或铽的重稀土化合物被用来提高磁性能,比如用重稀土Dy[11]、DyO[12]、DyF3 [13]、DyH2[14]、Pr-Cu或Dy-Cu[15-16]被当做扩散源来提高磁性能、热稳定性等.此外,Al也可显著提高钕铁硼稀土永磁体的矫顽力,降低磁通不可逆损失,hirr < 5 %的最高温度可达230 ℃[17], 通过显徽组织分析表明,Al对显徽组织的影响主要发生在富Nd相内.烧结时, 富Nd液相内溶有一定量的Al.冷却时,Al在富Nd相内形成富Al区和含Al较高的粒子,富Nd液相内的Al可改善其与Φ相的湿润性,从而提高磁体的矫顽力.同时,Ga的添加能够改变永磁体的取向特性和磁性能,添加Ga后的Nd(Fe-Ga)B永磁体的矫顽力有了明显的提升[18].由于低熔点合金熔点低,比较容易通过晶界扩散到磁体内部.因此文中选用Dy70Al10Ga20三元低熔点合金作为扩散源对磁体进行扩散,研究并分析了扩散后磁体的磁性能、热稳定性、微观组织结构和物相结构.

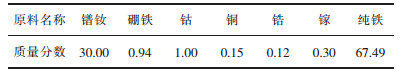

1 实验方法实验原始磁体选牌号为N52的烧结钕铁硼磁体,并将其进行线切割加工成尺寸为10 mm×10 mm×5 mm的小块磁体,其化学成分见表 1.将Dy、Al、Ga 3种元素按相应的配比Dy70Al10Ga20(指质量分数)进行称量好后,再经过高真空电弧熔炼系统,将3种金属熔炼成约为25 g的合金锭.随后经过高真空快淬系统让铜辊以8 m/s的速度将合金熔体甩成1 cm左右宽的片状合金.合金片制备好之后,采用贴片的方式将合金片贴在原始磁体的上下面并放入卧式烧结炉对其进行扩散热处理.磁体在扩散热处理之前需要经400目(0.037 mm)(指砂粒粗细大小,在任意每平方英寸(25.4 mm×25.4 mm)中有400个孔筛选出来的砂粒,下同)、800目(0.015 mm)、1 000目(0.013 mm)、1 500目(0.009 8 mm)、2 000目(0.006 5 mm)的砂纸进行打磨,用酒精超声波清洗后烘干待用.采用的扩散热处理工艺为一级回火热处理分别为810 ℃、830 ℃、850 ℃、870 ℃、890 ℃,时间均为4 h,二级回火热处理均为490 ℃×3 h,之后再用NIM-500C高温永磁测量仪测量磁体的磁性能,用MLA650场发射扫描电镜观察扩散前后组织微观图,用亥姆霍兹线圈提拉法测量腐蚀后样品的不可逆磁通损失,用Empyrean型X射线衍射仪测量了磁体的物相结构.

| 表 1 N52磁体成分/% Table 1 Composition of N52 magnet /% |

|

| 点击放大 |

2 结果和讨论 2.1 扩散Dy70Al10Ga20合金对烧结钕铁硼磁体物相的影响

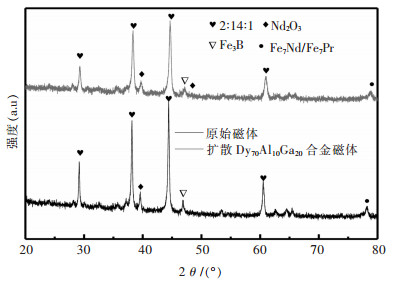

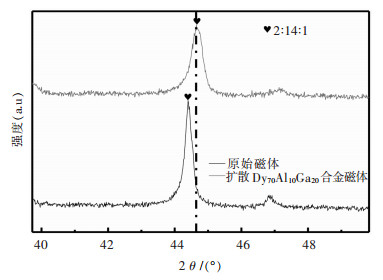

图 1所示为原始磁体和扩散Dy70Al10Ga20合金后磁体的XRD物相分析结果,可以看到除了有Nd2Fe14B的2:14:1主相外,还有一些杂相存在,它们主要分布在富钕相中,少量的存在会提高磁体的反向形核场.从图 2中可以看到Nd2Fe14B相峰在扩散Dy-Al-Ga合金后向右偏移,这是因为Nd2Fe14B晶格常数小于Dy2Fe14B,Dy2Fe14B(a=0.875 7 nm; c=1.199 0 nm); Nd2Fe14B(a=0.879 2 nm; c=1.217 7 nm)更小[19]. Dy取代Nd形成(Nd, Dy)2Fe14B相.

|

| 图 1 原始磁体和扩散Dy70Al10Ga20合金磁体的XRD衍射图谱 Fig. 1 XRD diffraction pattern of original and Dy70Al10Ga20 diffused alloy magnets |

|

| 图 2 XRD的2:14:1主相峰位置处局部放大 Fig. 2 Local magnification at 2:14:1 of the main phase peak of XRD |

2.2 扩散Dy70Al10Ga20合金对烧结钕铁硼磁体磁性能的影响

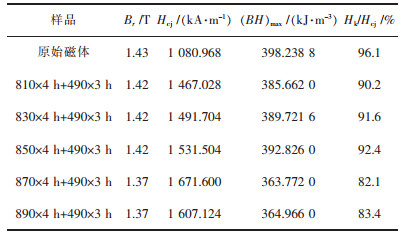

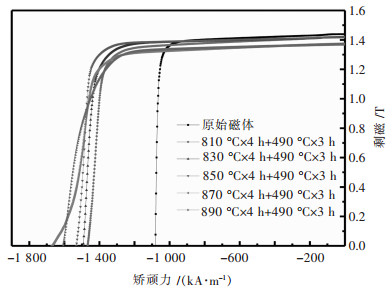

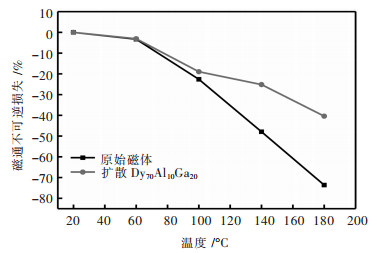

表 2和图 3表示的分别是原始磁体和不同温度扩散Dy70Al10Ga20合金后磁体的磁性能.从表 2与图 3中均可以看出,随着扩散温度地提高,磁体矫顽力呈现出先增加后降低地趋势.经过扩散后的磁体矫顽力从原始的1 080.968 kA/m最高提升到1 671.600 kA/m,增幅约为55 %.剩磁从原始的1.44 T下降到1.38 T,方形度由96 %下降到84 %,下降幅度较小.在870 ℃下扩散性能较优,因此,选用矫顽力提升最高的磁体测量热稳定性能、微观组织和物相结构.在高温情况下工作时,Nd-Fe-B磁体的磁性能会急剧下降,图 4对应于原始磁体和扩散Dy70Al10Ga20合金后磁体分别在20 ℃、50 ℃、80 ℃、120 ℃、180 ℃下暴露2 h的磁通不可逆损耗,随着温度的升高,原始磁体显现出急剧下降的趋势,而扩散后磁体磁通不可逆损耗下降趋势变缓,在任一温度点都优于原始磁体,在5个温度点中磁通不可逆损耗最高比原始磁体降低了33.23 %,晶界扩散Dy70Al10Ga20合金明显提高了Nd-Fe-B磁体的热稳定性.

| 表 2 原始磁体和扩散Dy70Al10Ga20合金后磁体的磁性能 Table 2 Magnetic properties of the original and diffused Dy70Al10Ga20 alloy magnet |

|

| 点击放大 |

|

| 图 3 原始磁体和扩散Dy70Al10Ga20合金后磁体的退磁曲线 Fig. 3 Demagnetization curves of original and Dy70Al10Ga20 diffused alloy magnets diffused Dy70Al10Ga20 alloys at different temperatures |

|

| 图 4 原始磁体和扩散后磁体的磁通不可逆损失 Fig. 4 Irreversible flux loss of original and diffused magnets |

2.3 扩散Dy70Al10Ga20合金对烧结钕铁硼磁体微观组织的影响

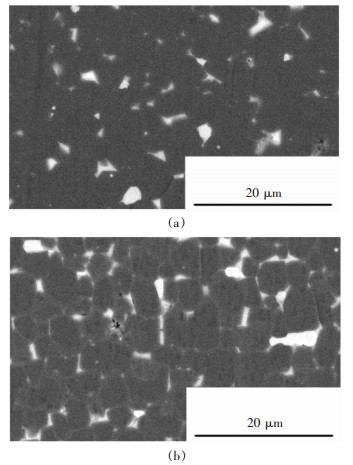

图 5所示为原始磁体和晶界扩散后磁体的显微组织图,图 5(a)是原始磁体的显微组织图,图 5(b)是扩散Dy70Al10Ga20合金后磁体的显微组织图.可以很明显看到,原始磁体的富Nd相较少且不连续,大块富Nd相占比较多,晶界模糊不连续,容易发生磁交换作用.而扩散三元合金后磁体的富Nd相明显增多且连续光滑,大块富Nd相占比较少,很好地隔绝了磁交换作用.在相邻晶粒之间的晶粒外延处可以看到颜色介于灰色和白色之间的灰白色区域,此灰白色区域为(Nd, Dy)2Fe14B核壳结构.核壳结构和连续富Nd相两者共同起到隔绝磁交换的作用[20].这也很好地解释了矫顽力增加的现象.

|

| 图 5 原始磁体和晶界扩散后磁体的显微组织 Fig. 5 The microstructure of original and GBDPed magnets |

3 结论

1)扩散Dy70Al10Ga20合金后磁体的微观组织明显优于原始磁体,晶界连续.基于XRD图谱分析重稀土元素进入主相外延层是导致磁性能显著提高的主要因素.

2)随着温度的升高,原始磁体磁通不可逆损耗显现出急剧下降的趋势,而扩散后磁体下降趋势变缓,在任一温度点都优于原始磁体,在5个温度点中磁通不可逆损耗最高比原始磁体降低了33.23 %,扩散Dy70Al10Ga20合金明显提高了Nd-Fe-B磁体的热稳定性.

3)与原始磁体相比,扩散Dy70Al10Ga20合金之后的磁体的矫顽力有了很大的提升,从1 080.968 kA/m显著提升到1 671.600 kA/m,提升幅度约为55 %,并且在高温下还表现出较高的矫顽力.

| [1] |

YANG J H, KIM M J, CHO S H, et al. Effects of composition and substrate temperature on the magnetic properties and perpendicular anisotropy of NdFeB thin films[J].

Journal of Magnetism and Magnetic Materials, 2002, 248(3): 374–378. |

| [2] |

HONO K, SEPEHRI-AMIN H. Strategy for high-coercivity Nd-Fe-B magnets[J].

Scripta Materialia, 2012, 67(6): 530–535. DOI: 10.1016/j.scriptamat.2012.06.038. |

| [3] |

李强. 钕铁硼永磁材料市场状况与发展前景[J].

有色金属科学与工程, 2001, 15(4): 38–40.

|

| [4] |

KOHASHI T, MOTAI K, NISHIUCHI T, et al. Magnetism in grain-boundary phase of a NdFeB sintered magnet studied by spin-polarized scanning electron microscopy[J].

Applied Physics Letters, 2014, 104(23): 1–5. |

| [5] |

高峰. 钕铁硼永磁材料的生产与应用现状[J].

有色金属科学与工程, 1996, 9(3): 36–37, 42.

|

| [6] |

WU Y Q, TANG W, KRAMER M J, et al. Correlation of the energy product with evolution of the nanostructure in the Y, Dy, Nd-(Fe, Co)-B magnetic alloys[J].

Journal of Applied Physics, 2009, 105(7): 2907. |

| [7] |

LI W F, OHKUBO T, HONO K, et al. The origin of coercivity decrease in fine grained Nd-Fe-B sintered magnets[J].

Journal of Magnetism and Magnetic Materials, 2009, 321(8): 1100–1105. DOI: 10.1016/j.jmmm.2008.10.032. |

| [8] |

CHUBB D L, PAL A M T, PATTON M O, et al. Rare earth doped high temperature ceramic selective emitters[J].

Journal of the European Ceramic Society, 1999, 19(13/14): 2551–2562. |

| [9] |

LOEWE K, BENKE D, KUBEL, et al. Grain boundary diffusion of different rare earth elements in Nd-Fe-B sintered magnets by e-xperiment and FEM simulation[J].

Acta Materialia, 2017, 124: 421–429. DOI: 10.1016/j.actamat.2016.11.034. |

| [10] |

K T H. PARK K, SAGAWA M. Effect of metal-coating and consecutive heat treatment on coercivity of thin Nd-Fe-B sintered magnets[C]// 16th Int. Workshop on Rare-Earth Magnets and Their Applications Sendai, Japan, 2000.

|

| [11] |

HU S Q, PENG K, CHEN H. Influence of annealing temperature on the Dy diffusion process in NdFeB magnets[J].

Journal of Magnetism & Magnetic Materials, 2017, 426: 340–346. |

| [12] |

LI D S, NISHIMOTO M, SUZUKI S, et al. Coercivity enhancement of Nd-Fe-B sintered magnets by grain boundary modification via reduction-diffusion process[C]// IOP Conference Series: Materials Science and Engineering, 2009.

|

| [13] |

TANG W, DENNIS K W, KRAMER M J, et al. Studies of sintered MRE-Fe-B magnets by DyF3 addition or diffusion treatment (MRE=Nd+Y+Dy)[J].

Journal of Applied Physics, 2012, 111(7): 07A. |

| [14] |

LIU W Q, CHANG C, YANG Y M, et al. Coercivity enhancement of sintered Nd-Fe-B magnets by grain boundary diffusion with DyH2 nanoparticles[J].

Journal of Magnetics, 2013, 18(4): 400–404. DOI: 10.4283/JMAG.2013.18.4.400. |

| [15] |

LU K, BAO X, TANG M, et al. Influence of annealing on microstructural and magnetic properties of Nd-Fe-B magnets by grain boundary diffusion with Pr-Cu and Dy-Cu alloys[J].

Journal of Magnetism and Magnetic Materials, 2017, 441: 517–522. DOI: 10.1016/j.jmmm.2017.03.049. |

| [16] |

OONO, NAOKO, SAGAWA, et al. Production of thick high-performance sintered neodymium magnets by grain boundary diffusion treatment with dysprosium-nickel-aluminum alloys[J].

Journal of Magnetism and Magnetic Materials, 2011, 323(3): 297–300. |

| [17] |

阎阿儒, 宋晓平, 王笑天. 添加Al、Mg、W、Mo对烧结Nd-Fe-B磁体磁性能与显微组织的影响[J].

中国稀土学报, 1998, 16(1): 13–17.

DOI: 10.3321/j.issn:1000-4343.1998.01.004.

|

| [18] |

泮敏翔, 葛洪良, 张朋越, 等. Ga和Ti掺杂NdFeB永磁体矫顽力的研究[C]//中国功能材料及其应用学术会议, 中国仪器仪表学会, 中国金属学会, 杭州, 2010.

http://cpfd.cnki.com.cn/Article/CPFDTOTAL-GNCL201010002013.htm |

| [19] |

JIN C, CHEN R, YIN W, et al. Magnetic properties and phase evolution of sintered Nd-Fe-B magnets with intergranular addition of Pr-Co alloys[J].

Journal of Alloys and Compounds, 2016, 670: 72–77. DOI: 10.1016/j.jallcom.2016.02.006. |

| [20] |

SUMIN K, DONG-SU K, HYUM-SOOK L, et al. Enhancing the coercivity of Nd-Fe-B sintered magnets by consecutive heat treatment induced formation of Tb-diffused microstructures[J].

Journal of Alloys and Compounds, 2019, 780: 574–580. DOI: 10.1016/j.jallcom.2018.11.412. |

2019, Vol. 10

2019, Vol. 10