| Nd取代对Pr-Nd-Fe-B烧结磁体耐腐蚀性的影响 |

2. 江西省稀土永磁材料及器件工程研究中心 江西 赣州 341000;

3. 江西理工大学工程研究院 江西 赣州 341000;

4. 江西师范大学物理与通信电子学院 江西 南昌 330022

2. Research Center for Rare Earth Permanent Magnet Materials and Devices Engineering of Jiangxi Province, Ganzhou 341000, China;

3. Institute of Engineering and Research, Jiangxi University of Science and Technology, Ganzhou 341000, China;

4. College of Physics, Electronics and Comunication, Jiangxi Normal University, Nanchang 330022, China

钕铁硼(Nd-Fe-B)磁体具有磁性能高、抗退磁能力强、易加工成型,以及易实现器件小型化、节能等优点,被广泛应用于电子通信、自动控制、新能源、节能电机等众多领域[1-2].由于考虑制造成本、资源平衡利用等因素,行业内普遍使用镨钕合金而非纯金属钕作为原料进行生产制成烧结Pr-Nd-Fe-B磁体.但是其耐腐蚀性能较差[2-7],易发生腐蚀[2, 8],致使磁体失效,制约了磁体的应用[1].

为此,科研工作者采用各种方法和手段对其耐腐蚀性行为开展了大量研究. ZHANG P等[9]采用Cu和Nb粉末联加作为改进剂改善钕铁硼磁体的耐腐蚀性;文献[10-11]通过添加Cu_(85)Sn_(15)和Cu/Al改善晶界从而提高磁体的耐腐蚀性;PAN M等[12]则采用Cu和Zr粉末联加改善磁体耐腐蚀性,ZHOU Q等[13]采用难熔金属Nb和Ti取代Fe来降低磁体PCT失重;2017年,王小二[14]利用Mg纳米粉添加到钕铁硼磁体里面,使之形成Mg-Nd晶界相,进而提高磁体的耐腐蚀性.但利用稀土元素Nd取代Pr的研究很少.

因此,结合钕铁硼行业的生产实际,采用Nd取代Pr-Nd制备烧结磁体,研究分析Nd取代对磁体HAST失重、腐蚀电位和微观结构的影响,为改进Pr-Nd-Fe-B烧结磁体的耐腐蚀性提供依据,这具有一定的实际意义.

1 实验材料与方法采用工业纯Nd、Pr-Nd合金、纯Fe和B含量为19 %的B-Fe合金为原料,按照Nd32Fe67.02B0.98和Pr7Nd25Fe67.02B0.98两种成分配比.利用将其分别制成平均厚度为0.3 mm的合金片,经氢碎、气流磨获得平均粒径为3.2 μm的磁粉,在2.1 T磁场下取向成型,经200 MPa冷等静压后进入真空烧结炉进行烧结、时效.烧结工艺为1 065 ℃×5.5 h,一级时效890 ℃×3 h,二级时效480 ℃×4.5 h,制得烧结磁体.再通过平面磨床、切片机和抛光机制得尺寸为10 mm×10 mm×10 mm的测试样品磁体.

采用高温加速老化试验箱(HAST,EHS-411M)测试磁体在131 ℃, 100 %RH, 0.202 MPa条件下的质量损失(失重),采用电化学综合测试仪(CHI660E)分别测试室温下磁体在0.1 mol/L HCl溶液、3.0 % NaOH溶液、3.5 % NaCl溶液中的动电位极化曲线,采用场发射扫描电子显微镜(SEM,SU1510)观察分析于HAST试验后磁体的微观组织形貌.

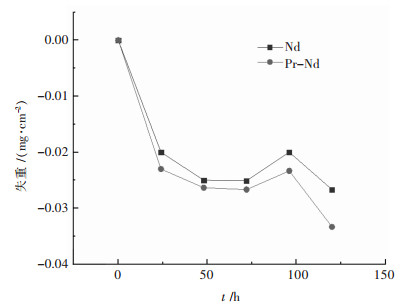

2 结果与讨论 2.1 对失重的影响2种不同成分的磁体分别经HAST试验24 h,48 h,72 h,96 h,120 h后的失重曲线如图 1所示.

|

| 图 1 Nd-Fe-B和Pr-Nd-Fe-B磁体HAST失重对比 Fig. 1 Mass loss comparison of Nd-Fe-B and Pr-Nd-Fe-B magnets by HAST |

经HAST老化120 h后,使用Pr-Nd合金为原料制备的磁体(Pr-Nd-Fe-B磁体)失重达到0.033 mg /cm2,明显大于使用纯Nd的磁体(Nd-Fe-B磁体)0.027 mg/cm2的失重.这表明使用纯Nd取代Pr元素后,磁体的耐腐蚀性转好.这主要得益于在化学元素周期表中Nd元素的位置较Pr靠后,其金属活泼性弱于Pr,较不容易发生氧化反应[15].

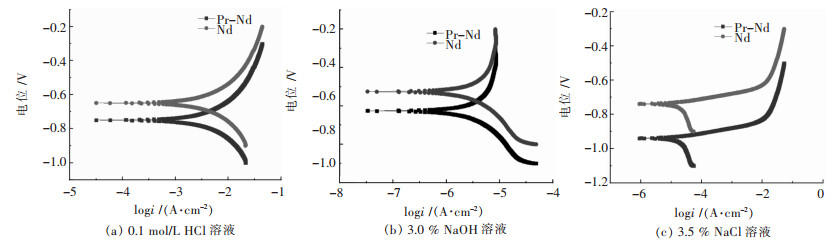

2.2 对腐蚀电位的影响图 2(a)~图 2(c)所示为室温下Nd-Fe-B和Pr-Nd-Fe-B 2种磁体分别在0.1 mol/L HCl溶液、3.0 % NaOH溶液、3.5 % NaCl溶液中的动电位极化曲线.从图 2中可见,室温时,在以0.1 mol/L HCl溶液为腐蚀介质条件下,Nd-Fe-B磁体腐蚀电位Ecorr(Nd-Fe-B,0.1 mol/L HCl)为-0.649 V,Pr-Nd-Fe-B磁体腐蚀电位Ecorr(Pr-Nd-Fe-B,0.1 mol/L HCl)为-0.736 V;在以3.0 % NaOH溶液为腐蚀介质条件下,Nd-Fe-B磁体腐蚀电位Ecorr(Nd-Fe-B,3.0 % NaOH)为-0.525 V,Pr-Nd-Fe-B磁体腐蚀电位Ecorr(Pr-Nd-Fe-B,3.0 % NaOH)为-0.625 V;在以3.5 % NaCl溶液为腐蚀介质条件下,Nd-Fe-B磁体腐蚀电位Ecorr(Nd-Fe-B,3.5 % NaCl)为-0.739 V,Pr-Nd-Fe-B磁体腐蚀电位Ecorr(Pr-Nd-Fe-B,3.5 % NaCl)为-0.94 V.由此可见,采用纯Nd取代Pr-Nd合金作原料后,磁体在不同腐蚀介质条件下的腐蚀电位均发生不同程度的正移,表明磁体的耐电化学腐蚀性能变好[16-19].

|

| 图 2 Nd-Fe-B和Pr-Nd-Fe-B磁体在不同腐蚀介质中的动电位极化曲线 Fig. 2 Potentiodynamic polarization curves of Nd-Fe-B and Pr-Nd-Fe-B magnets under different corrosive mediums |

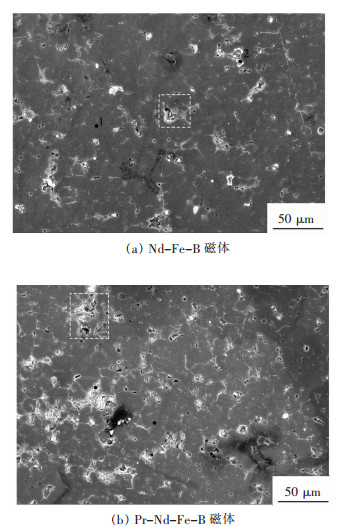

图 3所示为2种不同成分磁体的SEM二次电子像.该结果显示Pr-Nd-Fe-B磁体富稀土相分布不均匀(呈星云状聚集,图 3(b)).该分布易造成局部区域的富稀土相发生快速腐蚀,使整体腐蚀更为严重.而Nd-Fe-B磁体富稀土相团聚更少(图 3(a)),使腐蚀更轻微[20].表明用Nd取代Pr后,磁体的耐腐蚀性得到提高.这与前面所述结果一致.

|

| 图 3 2种磁体的SEM二次电子像 Fig. 3 Secondary electron images of the magnets by SEM |

磁体在二次电子像中不同衬度区域的EDS点测结果(表 1)表明,图 3中白色区域为晶界富稀土相,灰色区域为基体主相.

| 表 1 Nd-Fe-B和Pr-Nd-Fe-B磁体的EDS点测结果/% Table 1 EDS of Nd-Fe-B and Pr-Nd-Fe-B magnets /% |

|

| 点击放大 |

3 结论

1) 采用Nd完全取代Pr后,磁体的晶界相分布更加均匀,团聚现象减少,磁体HAST失重降低,腐蚀程度减轻.

2) 采用Nd完全取代Pr后,室温时在0.1 mol/L HCl溶液、3.0 % NaOH溶液、3.5 % NaCl溶液中都呈现出腐蚀电位正移现象,耐电化学腐蚀能力增强.

| [1] |

孔祥薇, 刘国征, 赵明静, 等. 烧结NdFeB永磁体的腐蚀性研究现状[J].

稀土, 2013, 34(6): 69–70.

|

| [2] |

LI X T, LIU W Q, YUE M. Corrosion evaluation for recycled Nd-Fe-B sintered magnets[J].

Journal of Alloys and Compounds, 2017, 699: 713–717. DOI: 10.1016/j.jallcom.2017.01.022. |

| [3] |

ZHANG P, LIANG L P, JIN J Y, et al. Magnetic properties and corrosion resistance of Nd-Fe-B magnets with Nd64Co36 intergranular addition[J].

Journal of Alloys and Compounds, 2014, 616: 345–349. DOI: 10.1016/j.jallcom.2014.07.085. |

| [4] |

ZHOU B, LI X, LIANG X, et al. Improvement of the magnetic property, thermal stability and corrosion resistance of the sintered Nd-Fe-B magnets with Dy80Al20addition[J].

Journal of Magnetism & Magnetic Materials, 2017, 429: 257–262. |

| [5] |

WANG Z, LIU W Q, ZHANG D T, et al. Enhancement of corrosion resistance in sintered Nd-Fe-B permanent magnet doping with different CuZn5 contents[J].

Rare Metals, 2017, 28(10): 812–815. |

| [6] |

吴泽轶. 低成本与高抗蚀性烧结Nd-Fe-B磁体工业生产关键技术研究[D]. 湘潭: 湘潭大学, 2008.

|

| [7] |

丁霞, 薛龙飞, 丁开鸿, 等. 烧结钕铁硼永磁合金在不同酸溶液中的腐蚀行为[J].

中南大学学报, 2016, 47(4): 1105–1109.

DOI: 10.11817/j.issn.1672-7207.2016.04.004. |

| [8] |

ZHOU B B, LI X B, CAO X J, et al. Improvement in coercivity, thermal stability, and corrosion resistance of sintered Nd-Fe-B magnets with Dy80Ga20 intergranular addition[J].

Chinese Physics B, 2016, 25(11): 1–5. |

| [9] |

ZHANG P, MA T, LIANG L, et al. Improvement of corrosion resistance of Cu and Nb co-added Nd-Fe-B sintered magnets[J].

Materials Chemistry & Physics, 2014, 147(3): 982–986. |

| [10] |

NI J, WANG Y, JIA Z, et al. Effect of intergranular addition of Cu_(85)Sn_(15) on magnetic and anti-corrosion properties of Nd-Fe-B magnets[J].

Rare Metal Materials & Engineering, 2016, 45(8): 2111–2115. |

| [11] |

NI J, XIN S, ZHOU S, et al. Effect of Cu/Al compound addition on anti-corrosive and magnetic properties of NdFeB sintered magnets[J].

Rare Metal Materials & Engineering, 2013, 42(12): 2536–2540. |

| [12] |

PAN M. Improvement of corrosion resistance and magnetic properties of NdFeB sintered magnets with Cu and Zr co-added[J].

International Journal of Electrochemical Science, 2016: 2659–2665. DOI: 10.20964/110402659. |

| [13] |

ZHOU Q, CHEN R, ZHUANG L, et al. Effect of refractory metal substitution on magnetic property and corrosion behavior of sintered NdFeB magnets[J].

Rare Metal Materials & Engineering, 2015, 44(10): 2376–2380. |

| [14] |

王小二. 纳米粉对烧结钕铁硼抗腐蚀性能的影响[D]. 沈阳: 沈阳工业大学, 2017.

|

| [15] |

吴维昌, 冯洪清, 吴开治, 等.

标准电极电位数据手册[M]. 北京: 科学出版社, 1991.

|

| [16] |

李家节. NdFeB磁体环境加速腐蚀行为研究[D]. 北京: 钢铁研究总院, 2012.

|

| [17] |

李家节, 周头军, 郭诚君, 等. 烧结NdFeB磁体耐蚀性及其腐蚀特征研究[J].

中国稀土学报, 2016, 34(1): 33–37.

|

| [18] |

李家节, 安桂焕, 郭诚君, 等. 烧结NdFeB磁体高温高压高湿加速腐蚀行为研究[J].

中国稀土学报, 2016, 34(5): 555–558.

|

| [19] |

ZHOU Q Y, LI G, LIU Z, et al. Influence of the electroplating pretreatment on corrosion mechanism of NdFeB magnets[J].

Journal of Rare Earths, 2016, 34(2): 152–157. DOI: 10.1016/S1002-0721(16)60008-X. |

| [20] |

周寿增, 董清飞, 高学绪.

烧结钕铁硼稀土永磁材料与技术[M]. 北京: 冶金工业出版社, 2011.

|

2018, Vol. 9

2018, Vol. 9